|

Are You Ready to Move from On/Off to Proportional Control but your Customers Aren't?

|

|

This is an ongoing battle for most of us. There is some pretty slick new technology out there that will make most equipment more efficient, safer, lighter, smaller, and even greener, but getting the end users and industries to adapt is quite another issue.

One of the simplest moves in this area from a valve standpoint is moving from bang/bang or On/Off control to proportional control. I use the word “simplest” quite loosely here, so let me explain.

There are still lots of industries out there where Manual Levers are KING and getting operators to move to joysticks, control panels, buttons and knobs is an uphill battle. I am not sure we will ever get away from the manual levers, but for those of you whose equipment is already electro-hydraulic, moving from on/off to proportional can be quite simple.

When looking at creating custom mono-blocks or custom manifolds, we all know that quantity plays a role in the cost-effectiveness of this option. So, if you needed one manifold for on/off and one for proportional, going the custom, mono-block option is probably not feasible. For example, if the majority of your machines use on/off, while only a few select customers see the advantages of proportional, designing the machine to accommodate two different custom manifolds is just not practical. But what if you could design one custom manifold block that can be either on/off or proportional by switching out the on/off valves with the equivalent proportional valves? In other words, you could use the same manifold block for 100% of your applications even though some of those applications are on/off and some are proportional. I will review an example and discuss a little about the cost implications, but for the most part, you will see that this option is very feasible.

Let’s take a sweeper application. In most cases on/off control of the brooms is sufficient and probably an industry standard, so most operators are used to it and therefore prefer it. However, having proportional broom control offers clear advantages, such as: slowing down the brooms for certain surfaces which could extend broom life, as well as having the option of controlling broom speeds for specific debris, which would improve productivity. A very cost-effective solution can be created by designing a custom manifold that uses on/off valves for the majority of users, but has the proportional option for the progressive users just by swapping out a cartridge. (Electrical scheme notwithstanding but I will discuss this later.) So, as the sweeper OEMs push to move their customers and industry to proportional, the packaging of the hydraulic valve system doesn’t have to change, keeping overall cost to a minimum.

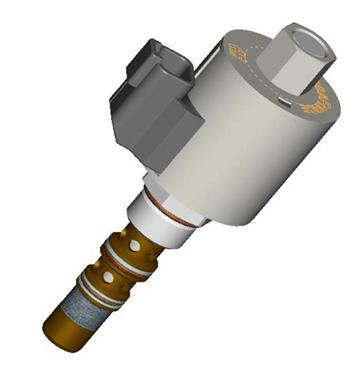

Below is a simplified version of the on/off circuit and the proportional circuit. The trick is that the port logic and cavity details must be exactly the same for both the on/off and the proportional valve. In this example, both valves use the VC12-3 cavity and both have the same port logic of open from port 1 to port 3 with port 2 blocked in the normal condition. And when energized, port 1 opens to port 2 blocking port 3 for the on/off, and proportioning flow from port 1 to port 2 while bypassing what isn’t needed to port 3. In this case, the valve hardware change is roughly $55.00 list per valve.

The advantage is that the end users can upgrade their equipment with a field kit from the OEM. As the industry moves toward proportional, and the mix of machines starts to change to more proportional than on/off, the OEM doesn’t have to create a new manifold. The manifold can be preconfigured so that it has commonality of parts, which means lower development cost and service costs, usage of the custom component (manifold in this case) remains consistent, longer machine production life, and so on.

To help you look at this as an option for your equipment development, here is a list of HydraForce on/off valves and their equivalent proportional valve partners having the same cavity detail and port logic:

On/Off Valves

Solenoid Operated

| Proportional Valves

Solenoid Operated |

SVxx-20

|

SPxx-20 |

| SVxx-21 |

SPxx-21 |

| SVxx-22 |

SPxx-22 |

| SVxx-25 |

SPxx-25 |

| SVCLxx-30 |

SPCLxx-30 |

| SVCLxx-31 |

SPCLxx-32 |

| SVxx-46R |

SPxx-46R |

| SVxx-47x |

SPxx-47x |

| SVxx-5x |

SPxx-5x |

| SV12-33 |

PV72-31 |

| SV08-33 |

PV08-31 |

| SV08-31 |

PV08-30 |

| SVRVxx-26 |

TSxx-26 |

| SV10-33 |

TS10-36 |

| Manually Operated |

|

| PR10-36 |

TS10-36 |

| RV08-20 |

TS08-20 / TS38-30 |

| RVxx-26 |

TSxx-26 |

| FRxx-32 |

ZLxx-30 |

| FRxx-33 |

PVxx-30 |

| FR12-23 |

PV72-20 / PV72-21 |

| FR16-20 |

PV16-23 |

| NV12-30 |

PV72-33 / PV72-35 |

| MR10-47 |

SP10-47 |

| MP10-47 |

SP10-47 |

| Piloted with On/Off Valve or Pressure Reducing/Relieving |

| SV08-33 |

EHPR08-33 |

| PDxx-S67 |

PExx-S67 |

Some of these conversions are pretty self explanatory, while other might be a bit confusing. Switching the SV08-20 with an SP08-20 is obvious. However, why would you switch from an SV08-33 directional selector to an EHRP08-33 proportional pressure reducing valve? In this case, these two valves would be used in conjunction with a pilot element. In our case the PD16–S67 would be piloted with the SV08-33 selector for the on/off version. If proportional directional control is needed, swapping out the PD with the PE metering element and using the EHPR proportional reducing valve will control pressure against the PE springs, which gives you the proportional movement of the metering spool.

In this case the additional valve hardware cost is less then $100 list.

A great feature for such a small price increase.

Another thing to keep in mind when designing a custom manifold solution for either option: the coils may or may not be identical when going from the on/off to the proportional. (My pricing comments include the coil changes.) In both of my examples, the SV12 spool valve coil was changed to the 70 size coil used on the PV’s and the SV08 coil was changed to an 06 EHPR coil. You can see how planning for adequate spacing of components on the manifold is critical. Check out our free i-Design software for easy manifold customization and configuration flexibility.

Depending on how your machine controllers are configured, a simple “patch’ download for proportional would cost virtually nothing. It’s hard to say where the costing for the electronics would fall. But doing your due diligence in the beginning and planning for this feature will definitely keep the costs down. Adding proportional electronics after the fact will be much more costly. There will, most likely, be some additional costs up front in terms of the controller, the software programming, and the input device, but how will that compare to your readiness when your customers and industry take the leap? Will you be ready?

For more in-depth electronics discussion, contact your local HydraForce expert.

About the Author:

Lisa DeBenedetto is a Regional Manager at HydraForce with more than 20 years of hydraulic experience. She has been with HydraForce for over 16 years. Contact Lisa