| What if I told you I could design a hydraulic system that functions the same or better than your current system, but with less cost, less space requirement, fewer leak points, better appearance and less assembly and installation time? First of all, would you even believe me? Secondly, why aren’t you doing it already? |

|

Well, everything I said is true. How we achieve a hydraulic system with less cost, less space requirement, fewer leak points, better appearance and less assembly and installation time, is to put it all into a big chunk of aluminum.

In the industry, we call a big chunk of aluminum with hydraulic valves in it a “manifold.” HydraForce will sometimes call it a “combination valve.” Whatever you call it, the idea is simple. We take all of the hoses and plumbing that would normally connect separate valve components in a complete system, and we turn those into drillings in that big chunk of aluminum.

Let’s talk about why it cost less. If you take ten different hydraulic valves to create a system, you may need thirty hoses and at least as many fittings to connect them all. On top of hose and fittings cost savings, the valves that go in a manifold cost less than separate and independent valves. Each of those individual valves requires its own “block” or “body” anyway. Why have ten of those when you can have one?

I think it’s easy to see how removing dozens of hoses and fittings and consolidating ten valves into one can save you space. This may not be as much as an issue with industrial applications (depending on the machine), but with a mobile machine, every inch of space is valuable real estate.

So now that we have fewer hoses, fewer connections and fewer components, we can see how we have reduced the number of points in which you can spring a hydraulic leak. Fewer leaks mean less money dripping away, and a reduced impact of the environment. There are very few hydraulic fluids that are environmentally safe, and the ones that are, are expensive enough to hold on to like a winning lottery ticket.

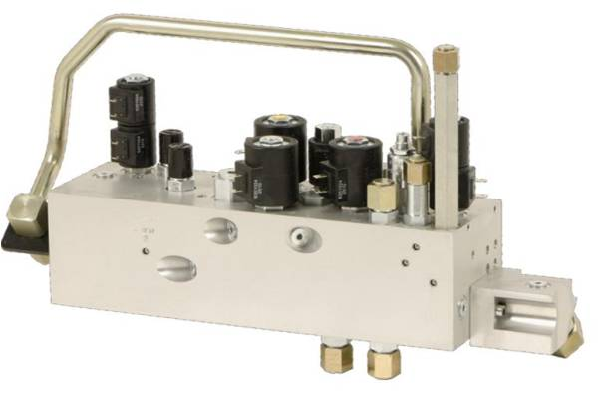

| Another benefit of a manifold design is the attractive appearance. It’s compact and shiny, and can be anodized any colour you wish. They leave you wondering what’s inside, and are great for keeping competitors from seeing how your system is plumbed together. Have a look at the photo on the right; does your hydraulic system look that good? |

|

Finally, you can’t beat the assembly and installation time of a manifold. Instead of spending hours plumbing separate components together, finding space to mount everything and crimping hoses until the wee hours of the night, you just mount the manifold and hook up your pressure, tank and work lines. Easy peasy, lemon squeezy!

Manifolds have infinite applications. There are 200 gallon per minute hydraulic presses which use slip in cartridge valves in a manifold, and there are simple one valve custom blocks. One of my customers had just one pressure reducing valve in a custom manifold with a gauge port, and six work ports. This valve didn’t save them any money on the valve itself, but saved them a ton of time during installation and saved hose/fitting costs because it replaced a mess of tees, junctions and connections.

Another advantage of a cartridge valve and manifold system is that the entire hydraulic circuit can be created and quoted using iDesign software, which is free to anyone who wants it. A system can be created, including positioning of the valves on the block in their 3D model interface. Distributors have access to the pricing function of the software, and we can quote a manifold you designed in seconds. The only real downside is the engineering and manufacturing time. You generally have to plan 6-8 weeks ahead to get a system in your hands.

If anyone wants the free software, you can download it here, or shoot me an email and I’ll gladly bring a copy out and show you how to use it.

_______________________________________________________

Josh Cosford is a certified hydraulic specialist working in sales for The Fluid Power House (Cambridge) Inc. in Ontario Canada: http://fluidpowerhouse.com/

Contact him at joshc@fluidpowerhouse.com or call (519)-624-7109

He has also contributed articles as a guest writer to Hydraulics and Pneumatics.

Follow him on Twitter: http://twitter.com/#!/FluidPowerTips

Follow him on Faacebook: http://www.facebook.com/#!/pages/Fluid-Power-Tips-by-Josh-Cosford/173198689366042