| Holy turbo chargers! When it’s a boost valve! |

HydraForce Insider Blog

When is a pressure reducing valve not a pressure reducer?

Posted by David Price on Tue, May 31, 2011 @ 08:05 AM

Tags: cartridge valves, Load Sensing, pressure control valve, logic valves, pressure reducing valves

Combining Cartridge Valves to Create a Versatile Flow Divider

Posted by David Price on Thu, Mar 17, 2011 @ 14:03 PM

Are you looking for an alternative for your Flow Divider circuit that will address the issues of multiple division, irregular percentage splits, adjustable ratios, inlet flow variance versus accuracy and pressure drop? If so, an alternative works for dividing pump flow only. If you need combining too, you might have to stick with the traditional flow divider / combiner (or read next week’s article to see a combining solution). |

Flow dividing circuits are used in many mobile applications to make full use of a varying input flow. Spool type dividers can be integrated into manifolds and are available in many sizes and fixed ratios. Although they can be cascaded, they are individually limited to a 2-way split. The valve ratios (i.e. 50/50 or 20/80) are fixed and factory preset by varying each spools flow specifications.

Tags: cartridge valves, proportional valves, Load Sensing, Cartridge Valve Pressure Compensators, benefits of cartridge valves, Flow Divider, hydraulic manifold design, pressure compensators

|

While there are many uses for L.S. priority valves, typically they are used to provide priority flow and/or pressure to certain components or functions depending on need. One of the most common uses is to apply them with L.S. steering orbitals. |

|

|

Static Steering Unit

|

Dynamic Steering Unit

|

|

|

Most Steering Circuits Utilizing Orbitals Use a Dynamic Setup

Since the steering unit is really just a rotary style variable orifice, using a pre-compensator in conjunction with it makes the steering function compensated. With a given steering RPM, the flow will remain constant regardless of varying load pressure. |

||

|

Ways to Fine-Tune the Circuit to Optimize Steering Performance

The pressure differential between the EC valve and the L.S. port of the steering unit is called the margin pressure. This pressure differential controls the responsiveness and the maximum steering flow. This is determined by a combination of the bias spring of the EC and boost orifice. |

||

| There are many other uses for L.S. Priority Valves as shown below: | ||

|

Proportional Steering and On/Off Lift Circuit

It is common to use proportional valves instead of steering orbitals to steer many types of equipment. This circuit simply gives priority to steering while allowing the excess flow to lift and lower a cylinder. The EC valve not only gives priority to steering, it also compensates the proportional valve so the same current value will achieve the same flow regardless of load. |

||

|

Priority Valve Working with Manual Valve

It is becoming more common to use an EC valve mounted to the inlet of a manual valve to give priority to certain functions while also limiting the maximum flow and pressure to those functions. |

||

|

Typical Priority-on-Demand

Most uses of the L.S. Priority Valves are for flow control. By sensing downstream of a fixed or variable orifice, you can compensate the circuit. The needle valve shown above could be any one of a number of components such as a ball valve, proportional valve, on/off valve or a simple orifice. |

Pressure Control Valve

Many people don't realize you can use an

|

|

Do you have another Priority Valve Application?

Do you have any questions about any of the circuits I describe here?

Shoot me an email if you’d like to share your application or ask a question.

About the Author:

Scott Parker is a Senior Application Engineer at HydraForce.

He’s been developing Hydraulic Systems for 20 years. Contact Scott

Tags: cartridge valves, Load Sensing, Priority Valves, Hydraulic Steering Circuits, Load Sense Priority Valves, benefits of cartridge valves, pressure control valve

Proper use of an Orifice in a Hydraulic Integrated Circuit

Posted by David Price on Wed, Mar 09, 2011 @ 12:03 PM

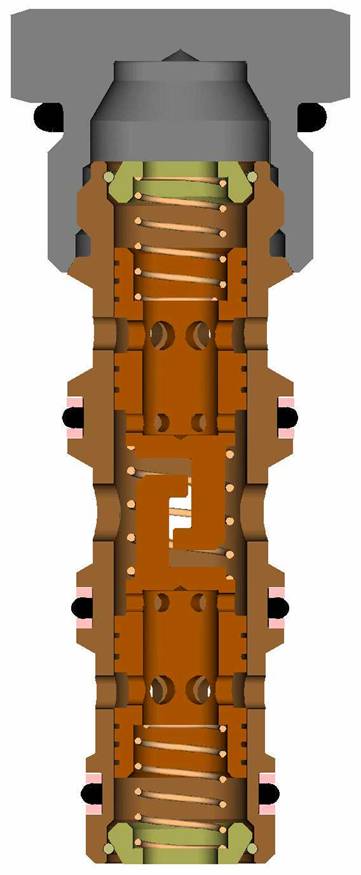

The proper performance of a hydraulic system is usually attributed to major components such as the motor, pump and valves. However, there is another unsung component that contributes equally to a system's overall performance: the orifice. In most traditional main hydraulic valves, orifices are built into the casting or dismounting components mold by the component’s constructors. In a cartridge valve manifold (otherwise known as a hydraulic integrated circuit), you start with a blank sheet of paper. Therefore, it is important to know where and when an orifice can change the performance of your system. |

|

The orifice is one of the most versatile components that we can add in our hydraulic circuit. The orifice can be used to limit the amount of oil in one part of our system, to bleed a pressure line to tank, or to transform a nervous and aggressive circuit into an efficient and highly controlled one. Often times the orifice has to simultaneously manage a very small amount of oil, control a dynamic flow rate and dump a system’s compensator. In many applications -- especially for hydrostatic transmissions -- it is important to control the dynamic pressure of the system to avoid pressure spikes and pressure ripple.

Tags: Load Sensing, pressure control valve, proportional flow control valve, combine pressure control valve and flow regulator, hydraulic integrated circuit, Orifices

Our hydraulic blog features cartridge valve application tips, circuit techniques, and industry news.

Posted by David Price on Tue, Feb 15, 2011 @ 13:02 PM

Our hydraulic blog features cartridge valve application tips, circuit techniques, and industry news.

Tags: Load Sensing, Priority Valves, Hydraulic Steering Circuits, Load Sense Priority Valves, Cartridge Valve Pressure Compensators